- Services

- Engineered Systems

- Engineering Services

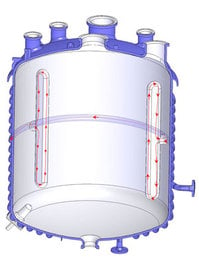

- OptiMix® Reactors

OptiMix® Reactors

Introducing the next generation of reactors - the new OptiMix®-HE

DDPS has extended the range of the OptiMix reactor to provide improved heat transfer and reduced processing times.

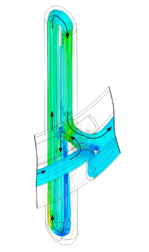

This new design circulates the thermal fluid contained in the half-coil through the baffles. This results in an increased heat transfer area up to 25% enabling a more homogeneity, faster thermal management and shortened cycle times.

Learn more about OptiMix:OptiMix Product Description

OptiMix is a patented reactor design that optimizes the mixing performance of glass-lined reactors by integrating three baffles on the vessel wall.OptiMix Features

OptiMix reactors are lined with 3009 Glass for superior corrosion resistance. All clamped-top/CTJ OptiMix reactors come standard equipped with a pitched-blade turbine; closed-welded/GL OptiMix reactors include a GlasLock agitator with adjustable blades. A fixed speed drive is vertically mounted to keep nozzles and accessories unobstructed for operational use. OptiMix baffles are also available in QVF borosilicate glass reactor designs.OptiMix Advantages

This innovative technology offers the following advantages:- Improved CIP efficiency by eliminating the difficult to clean top head pocket at the baffle/nozzle interface.

- Vortexing and splashing are significantly reduced, resulting in less product drying and sticking to the heated wall above the liquid surface.

- Design enhances heat transfer, solids suspension and distribution, gas dispersion, gas flow rates, and mass transfer through improved mixing.

- Eliminates the need for top entry baffles, freeing up an additional nozzle for process use

- The symmetrical baffling of the OptiMix reactor reduces shaft deflection and extends seal life by minimizing the bending loads that are imposed on the agitator shaft.

OptiMix Specifications

- Volumes from 30 to 2,000 gallons (clamped-top/CTJ series)

- Volumes from 300 gallons (closed-welded/GL series)

- Pressures from full vacuum to 90/150 psig (6/10 bar)

- Temperatures from -20°F (-30ºC) to 500°F (260ºC)

OptiMix Reactor System Profiles

System

System

Specialty Chemical Production Plant

Location

Western USADescription of Equipment

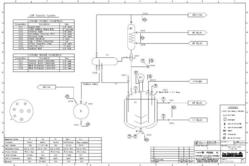

Four De Dietrich glass-lined steel OptiMix reactors systems, 200 and 500 gallon capacity with: Ta overhead condensers

Ta overhead condensers- Contained solid charging

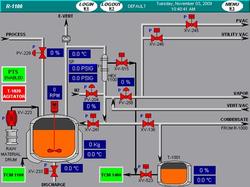

- HTM’s

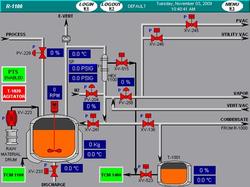

- Automation and controls

- Full function Factory Acceptance Test with water batches

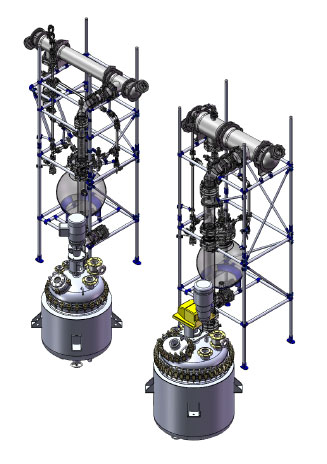

System

API Production FacilityLocation

Eastern USADescription of Equipment

Two 100 gallon De Dietrich glass-lined steel OptiMix reactors systems with: QVF glass piping and condensers

QVF glass piping and condensers- Custom layout for low ceiling installation

System

Specialty Chemical Production PlantLocation

Western USADescription of Equipment

QVF Q Series 100 liter reactor and 30 liter receiver featuring: Glass vessels and overheads

Glass vessels and overheads - Phase separator

- Mobile structures

- HTM’s

System

System

High-potency API (HPAPI) development and manufacturing

Location

Midwest USA

Description of Equipment

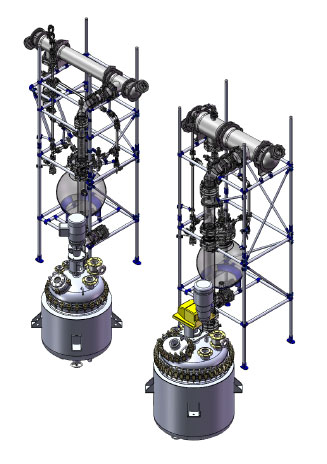

2 De Dietrich glass-lined steel OptiMix reactors systems, 100 and 200 gallon capacity, with:

- Shell and tube overhead condensers

- Dual receivers and interconnecting piping

- Full function Factory Acceptance Test

System

System Ta overhead condensers

Ta overhead condensers

QVF glass piping and condensers

QVF glass piping and condensers

Glass vessels and overheads

Glass vessels and overheads  System

System