- Services

- Integrated Systems

- Engineering Services

- Control Systems

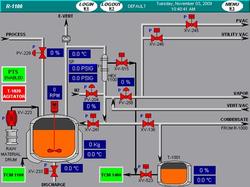

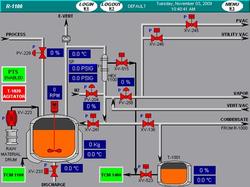

Control Systems

De Dietrich Process Systems offers complete process control systems capable of operating batch reactors, filter-dryers, vacuum systems, heat transfer packages, and the other process operations and downstream equipment. Through the utilization of our in-house expertise and experience, DDPS can provide cost-effective, safe, user-friendly, fully tested and documented control systems.

Key to DDPS’ control systems is the flexibility to integrate the system into customer existing platforms or plant standards. Some components of a typical offering are:

- Control Systems: PLC, DCS, & PC based.

- Engineering, Programming, and Documentation

- Control Panels & Operator Interfaces approved for Hazardous Locations

- Validation Assistance Packages

- Integration with Plant Control Systems & Equipment

- Start-Up, Commissioning, & Training On-Site

Fully-Integrated Control System Profiles

System

System

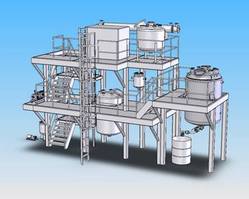

Specialty Chemical Production Plant

Location

Western USADescription of Equipment

Four De Dietrich glass-lined steel OptiMix reactors systems, 200 and 500 gallon capacity with: Ta overhead condensers

Ta overhead condensers- Contained solid charging

- HTM’s

- Automation and controls

- Full function Factory Acceptance Test with water batches

System

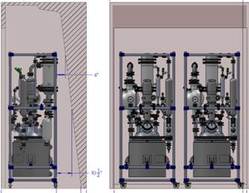

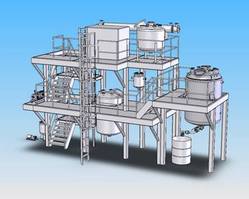

Specialty Chemical Production PlantLocation

Eastern USADescription of Equipment

One De Dietrich glass-lined steel reactors system, 1,000 gallon capacity with: Stainless steel charge tank and overhead condenser

Stainless steel charge tank and overhead condenser- Heat Transfer Module

- Automation and Controls

- 3D modeling to expedite approval and delivery

System

Industrial Chemical Production PlantLocation

Gulf Coast USADescription of Equipment

Sulfuric acid dilution system with:- 98% to 70% at 15 gpm

- QVF glass for corrosion resistance and temperature

- Automation and controls/PLC

System

Semiconductor Production Plant:Location

Pacific NW USADescription of Equipment

QVF single stage, vacuum evaporator system, 35-50 gph rated with:- Vertical titanium tube /Model D evaporator

- Multiple material of construction for economy (FRP/Ti/Alloy20/TFE/stainless steel)

- Push button start/stop, PLC controlled

System

Plating PlantLocation

Midwest USADescription of Equipment

QVF single stage, vacuum evaporator system, 75 gph rated with:- Vertical Nb tube /Model RBW evaporator

- Multiple material of construction for economy (Nb/Glass/TFE/stainless steel)

- Push button start/stop, PLC Controlled

System

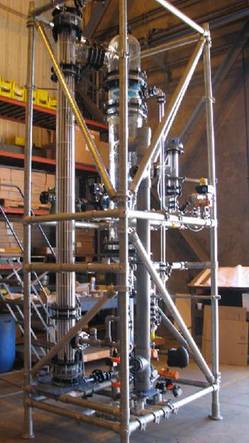

Training/Instructional Column System

Training/Instructional Column SystemLocation

Southeast USADescription of Equipment

QVF glass process system with:

- Dual 8" x 20 stage distillation columns

- Delta V control system

- Turnkey Installation

System

System

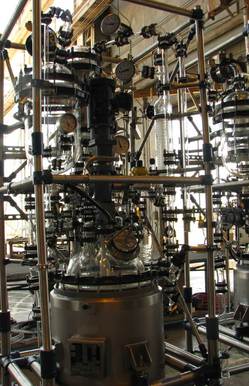

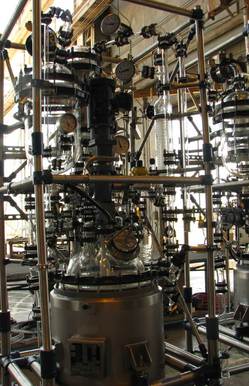

API Kilo PlantLocation

Southeast USADescription of Equipment

Dual 40 liter kilo plant with:- De Dietrich glass-lined steel VERI reactors

- QVF glass overheads, intermediate vessels

- Mobile charging/transfer system

- Budzar thermal oil systems

- Vacuum system

- PLC controlled

For more information about fully-integrated control systems see our page on Nitric Acid Concentration and Sulfuric Acid Concentration

Back to top

System

System Ta overhead condensers

Ta overhead condensers

Stainless steel charge tank and overhead condenser

Stainless steel charge tank and overhead condenser

System

System